Reliable Supplier Sawdust Making Machine - Air FLow Pipe Dryer – Shindery

Reliable Supplier Sawdust Making Machine - Air FLow Pipe Dryer – Shindery Detail:

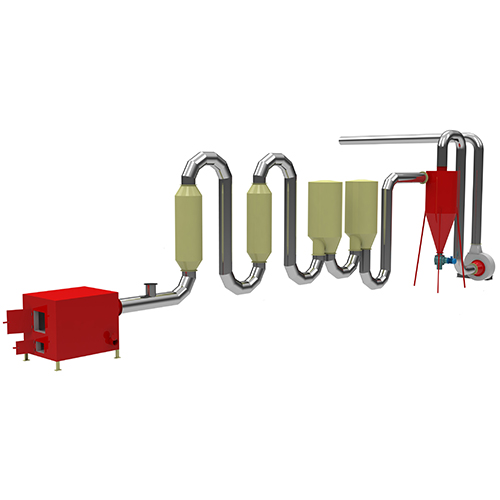

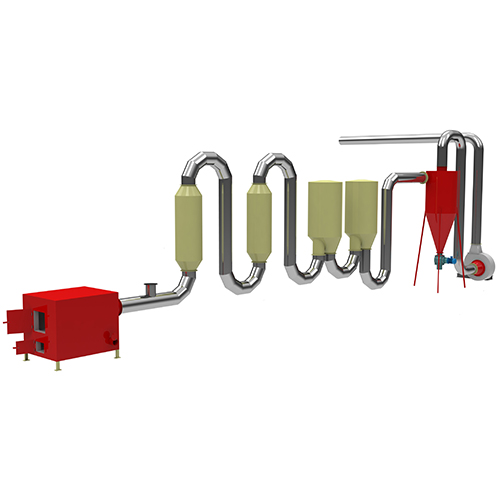

This kind of dryer is mainly used to prepare suitable moisture raw material for biomass pellet press. It is only to control the moisture of raw material at a reasonable range that can make good result of biomass pelletizing. Or the pellets will be broken because of too loose or too dry.

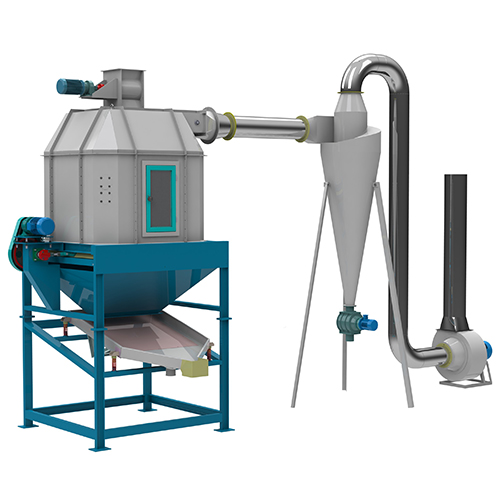

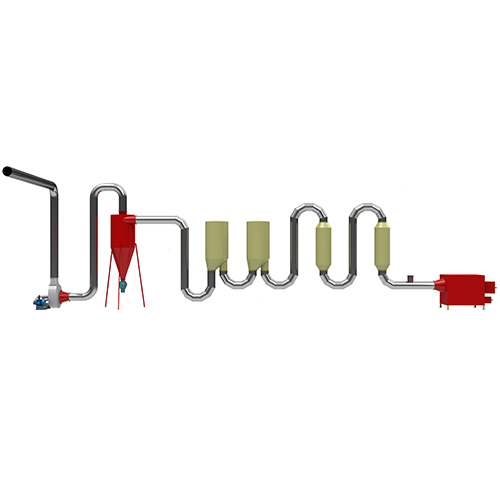

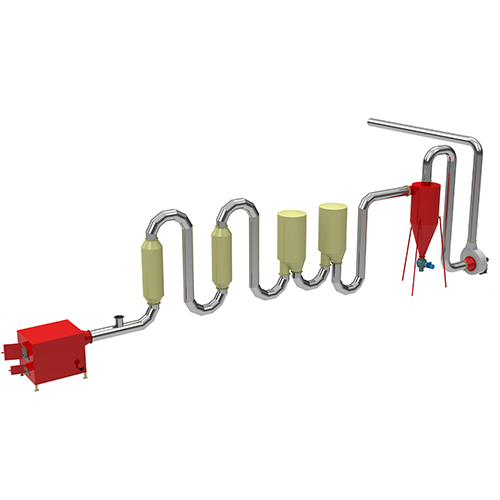

The whole system consists of fan blower, motor engine, fuel boiler, steel pipe, cyclone and air lock. In this system, wet material is input into hopper by screw feeder. Fuel furnace produces large volume of hot air. Those hot air is driven into steel pipes, mixed with wet sawdust and moved through curving pipes and drying chamber by the power of fan blower. Fast moving hot air sustains and is mixed with raw material sent by spiral feeder in the suspending state through the steel pipe; moisture evaporates as the material traverses along the steel pipe and is rendered dry at the discharge end. Humid air is continuously exhausted, thus the material is dried.

|

Model |

QHJ-1 |

QHJ-2 |

|

Dimension of Stove (m) |

1.1*1.0*1.0 |

1.5*1.2*1.2 |

|

Dia of Pipe (mm) |

219 |

325 |

|

Dia of Cyclone (mm) |

600 |

1000 |

|

Dia of Small Buffer Silo (mm) |

- |

636 |

|

Dia of Big Buffer Silo (mm) |

580 |

950 |

|

Induced Draft Fan (kw) |

5.5 |

11 |

|

Speed Adjustable Screw Feeder (kw) |

1.5 |

1.5 |

|

Total Length (m) |

11.8 |

14.6 |

|

Total Weight (t) |

2.2 |

3.2 |

|

Capacity (kgs/h) |

300-500 |

800(totally 2 small buffer silo and 2 big buffer silo,can be combined freely to realize biggest capacity or best drying effect.) |

Sawdust air flow pipe dryer

Product detail pictures:

Related Product Guide:

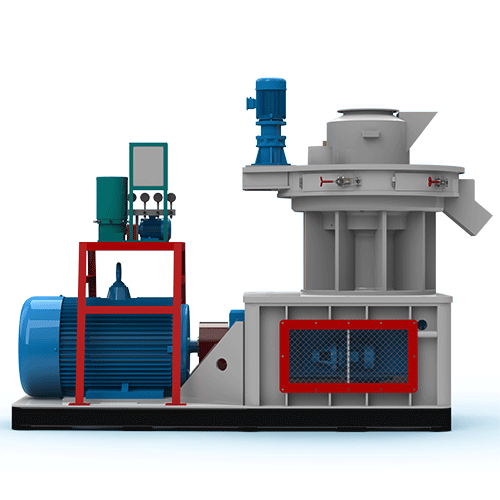

Bent Creek study tests method for reversing oak decline | Sawdust Pelleting Machine

Global Hybrid Solar Wind Energy Storage Market 2019 – Siemens Gamesa Renewable Energy, ReGen Powertech, General Electric | Hickory Wood Pellet Machine

Having a positive and progressive attitude to customer's fascination, our organization constantly improves our solution high-quality to fulfill the requirements of shoppers and further focuses on safety, reliability, environmental prerequisites, and innovation of Reliable Supplier Sawdust Making Machine - Air FLow Pipe Dryer – Shindery , The product will supply to all over the world, such as: Miami , Lisbon , Italy , Our R&D department always designs with new fashion ideas so we could introduce up-to-date fashion styles every month. Our strict production management systems always ensure stable and high quality products. Our trade team provides timely and efficient services. If there are any interest and inquiry about our products, please contact us in time. We would like to establish a business relationship with your honored company.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!