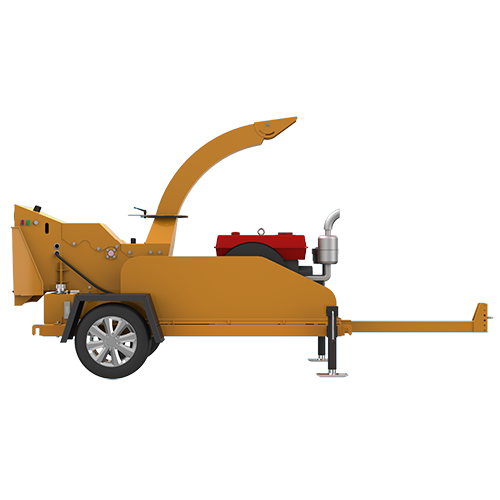

Personlized Products Industrial Wood Chipper Shredder - Drum Wood Chipper – Shindery

Personlized Products Industrial Wood Chipper Shredder - Drum Wood Chipper – Shindery Detail:

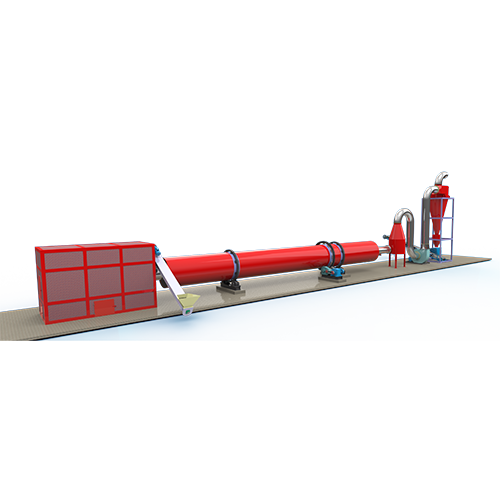

Shindery drum wood chipper main used to make wood chips, raw materials can be round wood, square blocks, wood staff etc.

| Model/Item |

BX215 |

BX216-3 |

BX218-6 |

|

Feeding Conveyor(length, m) |

6 |

6 |

8 |

|

Discharging Conveyor(length, m) |

13.6 |

13.6 |

13.6 |

|

Inlet Dimension(mm) |

160*400 |

230*500 |

300*680 |

|

Blades Qty(pcs) |

2 |

3 |

6 |

|

Knife Roll Diameter(mm) |

500 |

600 |

800 |

|

Knife Roll Speed(rpm) |

592 |

590 |

650 |

|

Max. Chipping Diameter(mm) |

160 |

230 |

300 |

|

Size of Finish Chips (length*width*thickness, mm) |

20/25*20/25*5 |

20/25*20/25*5 |

20/25*20/25*5 |

|

Capacity(based on upper final size, t/h) |

3-5 |

5-8 |

10-12 |

|

Main Motor Power(kw) |

45 |

55 |

110 max |

|

Feeding Motor Power(kw) |

2.2 – 3 |

3 – 4 |

4 – 5 |

|

Discharging Motor Power(kw) |

3 |

3 |

3 |

|

Oil Pump Motor Power(kw) |

1.5*1 |

1.5*1 |

1.5*1 |

|

Machine Weight(kg) |

2990 |

4070 |

7000 |

|

External Dimension(mm) |

1470*1550*970 |

1800*1900*1210 |

2200*2150*1500 |

Raw wood chipper machine,drum wood chipper machine

Product detail pictures:

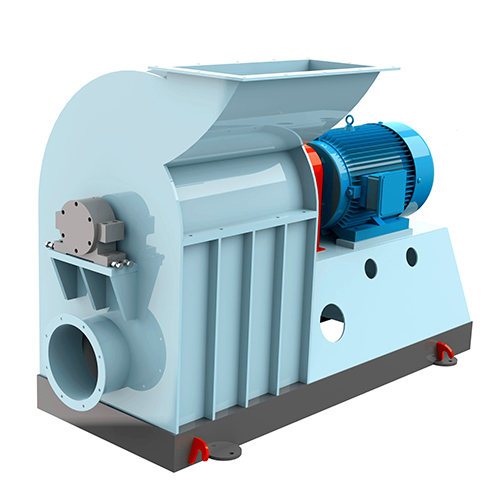

Related Product Guide:

Daily Pro Wrestling History (03/27): Randy Savage wins WWF title at WrestleMania IV | Electric Branch Shredder

Slovak company “Novovital” launched production of wood pellets and briquettes from wood waste | Efb Pellet Machine

With this motto in mind, we have turn out to be amongst probably the most technologically innovative, cost-efficient, and price-competitive manufacturers for Personlized Products Industrial Wood Chipper Shredder - Drum Wood Chipper – Shindery , The product will supply to all over the world, such as: Slovakia , Serbia , Bolivia , If any product meed your demand, remember to feel free to contact us. We're sure your any inquiry or requirement will get prompt attention, high-quality merchandise, preferential prices and cheap freight. Sincerely welcome friends all over the world to call or come to visit, to discuss cooperation for a better future!

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.