OEM Supply Rotating Drum Dryer - Rotary Drum Dryer – Shindery

OEM Supply Rotating Drum Dryer - Rotary Drum Dryer – Shindery Detail:

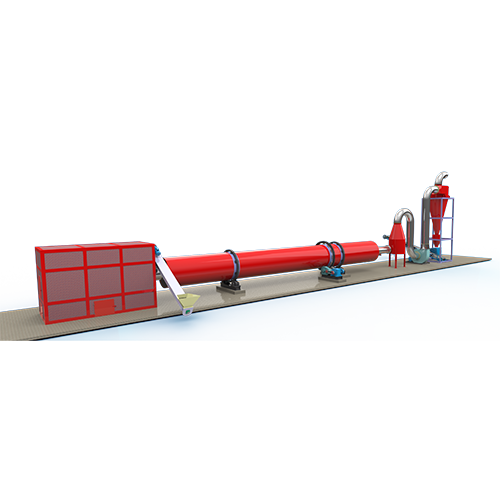

Rotary drum dryer is also called roll dryer, which is handling by bringing it into direct contact with a heated gas. The dryer is made up of a large, rotating cylindrical tube.

The dryer slopes slightly so that the discharge end is lower than the material feed end in order to convey the material through the dryer under.

The dryer can dry many kinds of materials which contain moisture, such as grain, cayenne pepper, fruit pomace, pond mud, coal, coal slurry, industrial waste, and clay stone. The dryer is also widely used in building materials, metallurgy, and chemical industry. The most outstanding advantages are high dry capacity, smooth rotation, high productivity and low energy consumption.

Through continuable improvement, the machine could meet production needs of different countries. We’ve received a lot of praises from worldwide which means that our drying machine is a popular one. Our machine is a good kind of renewable green fule machine. It’s really a perfect combination of drying and cooling.

Working principle:

Material to be dried enters the dryer, and as the dryer rotates, the material is lifted up by a series of internal fins lining the inner wall of the dryer.

When the material gets high enough to roll back off the fins, it falls back down to the bottom of the dryer, passing through the hot gas stream as it falls.

This gas stream can either be moving toward the discharge end from the feed end (known as co-current flow), or toward the feed end from the discharge end (known as counter-current flow).

The gas stream can be made up of a mixture of air and combustion gases from a burner, in which case the dryer is called a direct heated dryer.

Alternatively, the gas stream may consist of air or another (sometimes inert) gas that is preheated. When the gas stream is preheated by some means where burner combustion gases do not enter the dryer, the dryer known as an indirect-heated type.

|

Model/Item |

DIA1.2*12 |

DIA1.8*14 |

DIA2.2*18 |

|

Drum Diameter(m) |

1.2 |

1.8 |

2.2 |

|

Drum Length(m) |

12 |

14 |

18 |

|

Drum Volume(m3) |

13.75 |

35.1 |

68.4 |

|

Drum Dryer Motor(kw) |

7.5 |

18.5 |

30 |

|

Fan Machine(kw) |

7.5 |

18.5 |

30 |

|

Height (max, m) |

2.5 |

3 |

3.6 |

|

Width (max, m) |

2.2 |

3.1 |

3.7 |

|

Capacity(t/h) |

1-2 |

3-4 |

5-6 |

|

Rotation Speed(rpm) |

5.8 |

3-5 |

3-5 |

|

Air Inlet Temperature(℃) |

700 |

700 |

700 |

|

Moisture of Raw Material(max, %) |

50 |

50 |

50 |

|

Moisture of Final Product(%) |

10-15 |

10-15 |

10-15 |

Sleeve type sawdust rotary drum dryer

Product detail pictures:

Related Product Guide:

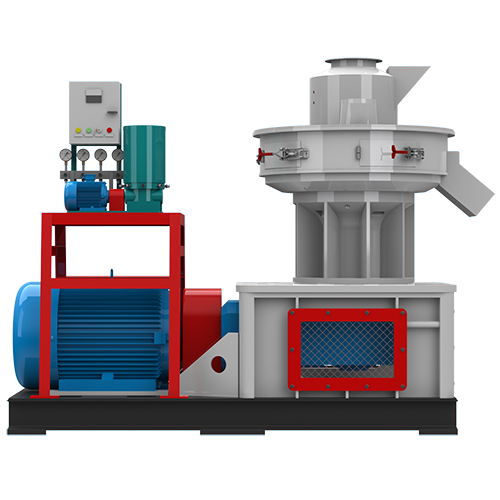

Hungry but too busy to go out? Food delivery options like UberEats are moving into Hall | Sawdust Pelleting Machine

Charred greens and smoked meats: Amos Dean’s carries on family legacy | Hickory Wood Pellet Machine

We can easily normally satisfy our respected buyers with our excellent high-quality, excellent selling price and good service due to we've been far more expert and more hard-working and do it in cost-effective way for OEM Supply Rotating Drum Dryer - Rotary Drum Dryer – Shindery , The product will supply to all over the world, such as: Norwegian , Turin , Lisbon , We are sticking to excellent quality, competitive price and punctual delivery and better service, and sincerely hope to establish long-term good relationships and cooperation with our new and old business partners from all over the world. Sincerely welcome you to join us.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!