OEM manufacturer Pellet Production Equipment - Air FLow Pipe Dryer – Shindery

OEM manufacturer Pellet Production Equipment - Air FLow Pipe Dryer – Shindery Detail:

This kind of dryer is mainly used to prepare suitable moisture raw material for biomass pellet press. It is only to control the moisture of raw material at a reasonable range that can make good result of biomass pelletizing. Or the pellets will be broken because of too loose or too dry.

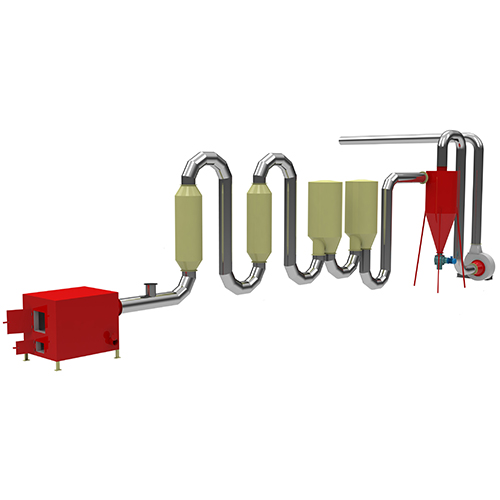

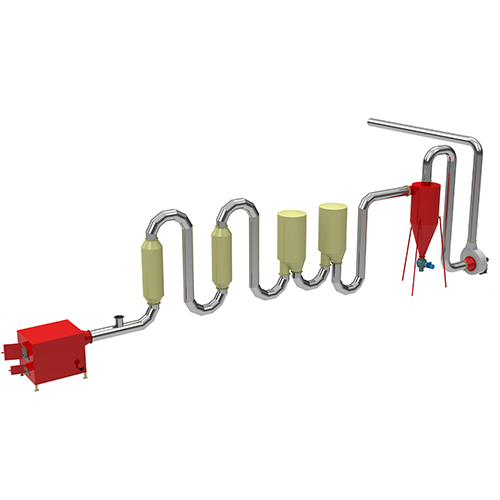

The whole system consists of fan blower, motor engine, fuel boiler, steel pipe, cyclone and air lock. In this system, wet material is input into hopper by screw feeder. Fuel furnace produces large volume of hot air. Those hot air is driven into steel pipes, mixed with wet sawdust and moved through curving pipes and drying chamber by the power of fan blower. Fast moving hot air sustains and is mixed with raw material sent by spiral feeder in the suspending state through the steel pipe; moisture evaporates as the material traverses along the steel pipe and is rendered dry at the discharge end. Humid air is continuously exhausted, thus the material is dried.

|

Model |

QHJ-1 |

QHJ-2 |

|

Dimension of Stove (m) |

1.1*1.0*1.0 |

1.5*1.2*1.2 |

|

Dia of Pipe (mm) |

219 |

325 |

|

Dia of Cyclone (mm) |

600 |

1000 |

|

Dia of Small Buffer Silo (mm) |

- |

636 |

|

Dia of Big Buffer Silo (mm) |

580 |

950 |

|

Induced Draft Fan (kw) |

5.5 |

11 |

|

Speed Adjustable Screw Feeder (kw) |

1.5 |

1.5 |

|

Total Length (m) |

11.8 |

14.6 |

|

Total Weight (t) |

2.2 |

3.2 |

|

Capacity (kgs/h) |

300-500 |

800(totally 2 small buffer silo and 2 big buffer silo,can be combined freely to realize biggest capacity or best drying effect.) |

Product detail pictures:

Related Product Guide:

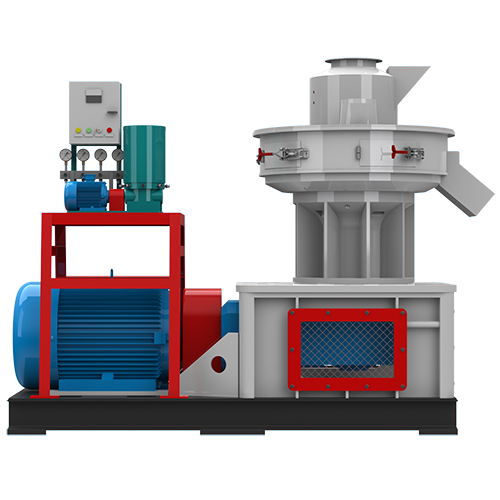

This Engineer Built a Real LightsaberKinda PCMagLogo.2016 Arrow_Path | Efb Pellet Machine

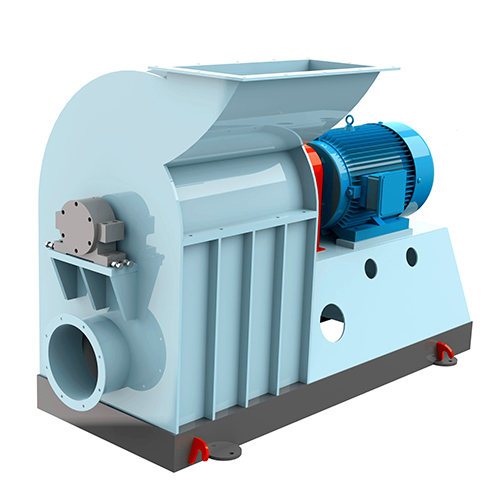

Traeger Timberline 850 review: BBQ goes high tech Engadget Engadget save share Close save share save share save share save share save share Page 1 Page 1 ear icon eye icon Fill 23 text file vr | Mobile Hammer Crusher

We now have a highly efficient crew to deal with inquiries from clients. Our intention is "100% shopper pleasure by our merchandise quality, price tag & our staff service" and take pleasure in a very good standing amongst purchasers. With quite a few factories, we can easily provide a wide vary of OEM manufacturer Pellet Production Equipment - Air FLow Pipe Dryer – Shindery , The product will supply to all over the world, such as: Belarus , Atlanta , Florida , We also have good cooperation relationships with many good manufacturers so that we can provide almost all of auto parts and after-sales service with high quality standard,lower price level and warmly service to meet demands of customers from different fields and different area.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!