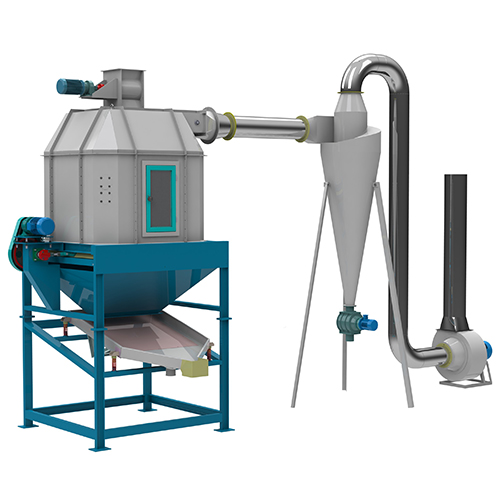

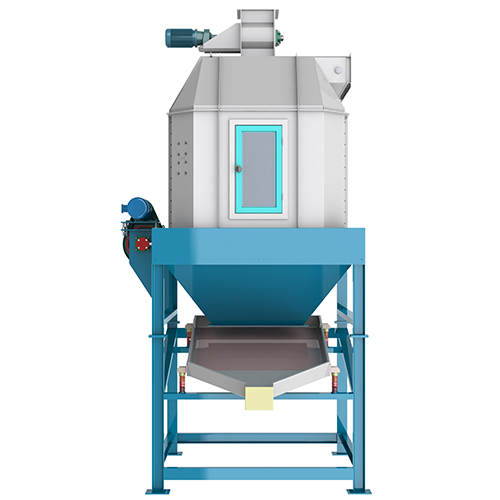

OEM Factory for Drum Dryers For Wood Chips - Counter Flow Cooler – Shindery

OEM Factory for Drum Dryers For Wood Chips - Counter Flow Cooler – Shindery Detail:

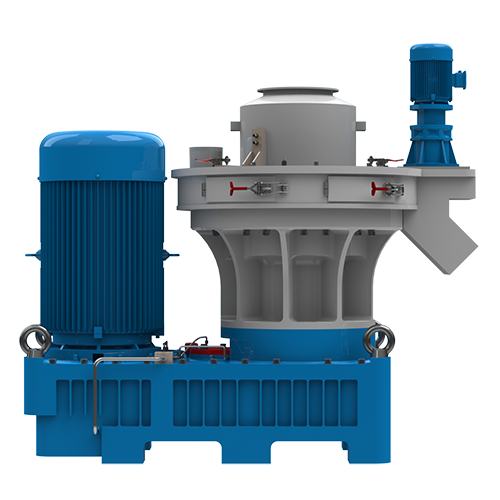

After pelletizing process,the pellet temperature will be about 70-80 degrees, and contain a certain amount of moisture. Use pellet cooler, can reduce the temperature of wood pellet,and during this process,the moisture will also reduce about 3%,to make sure the pellets can be easy storing.

FEATURES

(1)The counter flow cooler adopt counter. Current cooling principle to cool down the pellets wish high temperature and humidity, which avoid pellet cracking by the direct contact between hot pellets and cold airflow. so there is no quick chilling happens and pellet surface cracking can be prevented.

(2)Use closed unloader with large inlet area, so the cooling effect is significant.

(3)Adopts slide valve or tilting discharge mechanism with smooth and reliable motion, less pellets remain.

(4)Low energy consumption, easy to operate.

|

Model |

SKLN-3 |

SKLN-6 |

|

Inlet Air Lock (kw) |

0.55 |

0.75 |

|

Cooler Motor (kw) |

0.75 |

1.1 |

|

Vibration Screener (kw) |

0.12 |

0.12 |

|

Discharge Air Lock (kw) |

0.55 |

0.75 |

|

Bolwer (kw) |

5.5 |

7.5 |

|

Capacity (cool biomass pellets, t/h) |

2-6 |

6-9 |

|

External Dimension of Cooler (mm) |

2600×1700×3160 |

2700×2200×4225 |

Product detail pictures:

Related Product Guide:

Beer Calendar: Fresh Peaches, Fresh Lagers and the Fresh Hop Festival | Electric Branch Shredder

10 BattleBots That Are Sad And Weak (And 10 We Want Protecting Us) | Mobile Hammer Crusher

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of OEM Factory for Drum Dryers For Wood Chips - Counter Flow Cooler – Shindery , The product will supply to all over the world, such as: Saudi Arabia , New Zealand , Japan , By continuous innovation, we will provide you with more valuable products and services, and also make a contribution for the development of the automobile industry at home and abroad. Both domestic and foreign merchants are strongly welcomed to join us to grow together.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.