Welcome to our company websites!

News

-

Precautions for using dryer during wood sawdust pelletizing process

In order to get high quality final products during wood sawdust pelletizing process, it is very important to control the moisture of raw materials. Absolutely SHINDERY inner sleeve type rotary drum dryer is ideal equipment that can satisfy this requirement fully. For this kind of dryer, open foll...Read more -

SG500x600 hammer mill & LGX560 pellet mill for Denmark

Shindery made two sets of SG500x600 hammer mill and LGX560 pellet mill for Denmark customer.These equipments have been installed and commissioned, and will be put into use soon.These equipments are mainly used for producing high quality pine wood sawdust pellets. Features of LGX560 pellet m...Read more -

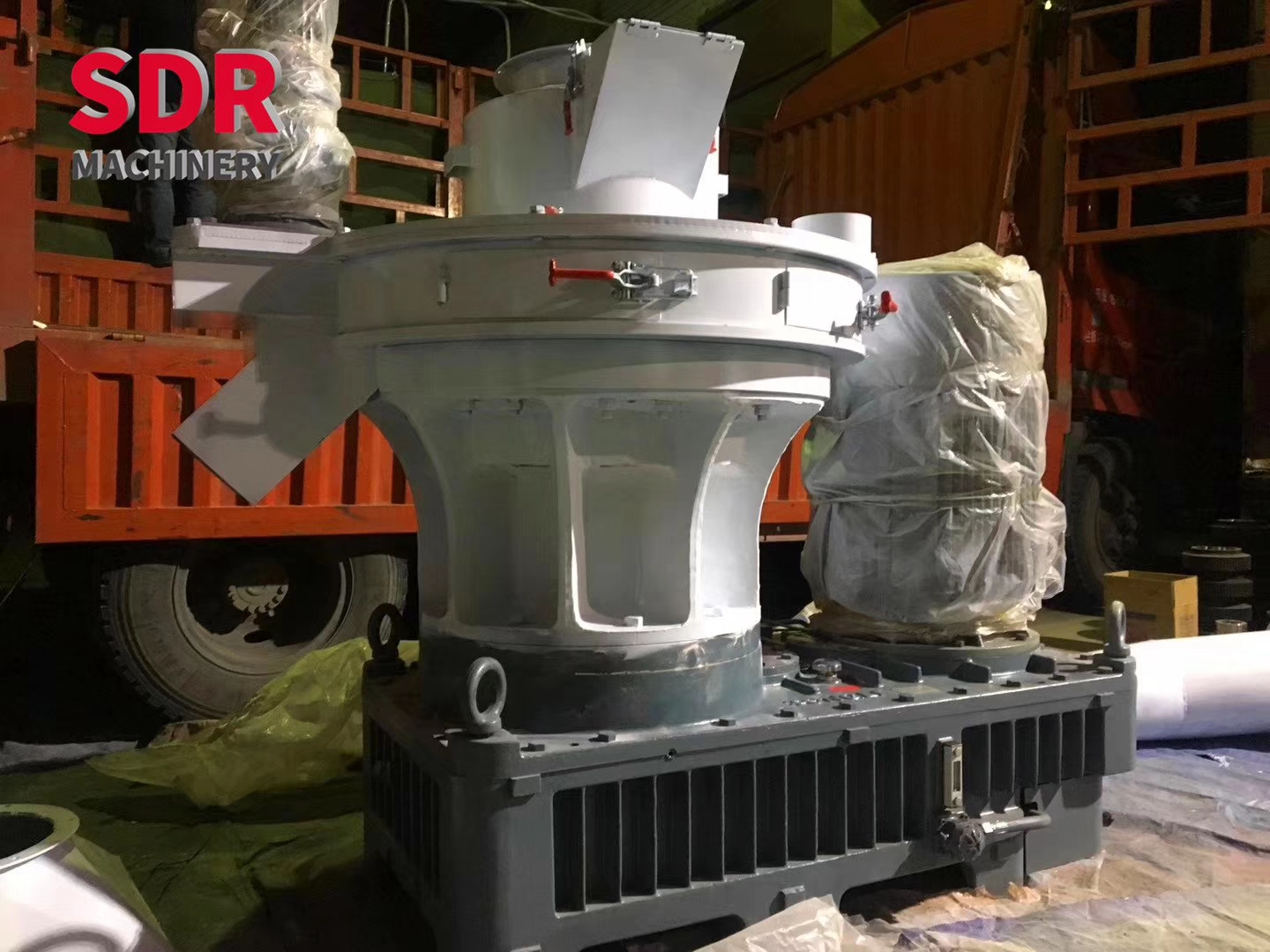

Delivered LGX600A model rice husk pellet machine to customer

On February 14th, we delivered one set of LGX600A model rice husk pellet machine to customer in Anhui province.Customer is using rice husk from rice milling line to produce pellets. After inspection,comparison and test, customer is more satisfied with our machine and so finally chosed LGX600A. ...Read more -

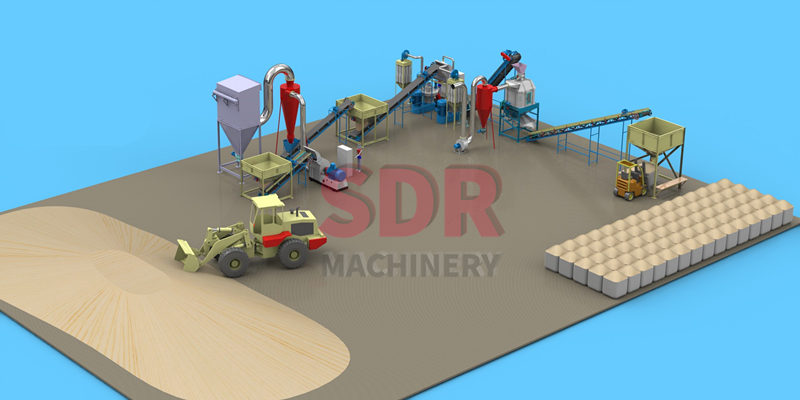

4-5tph beech and hornbeam wood pellet making line construction completed in Romania

In December 2019, our installers returned from Romania and successfully completed the installation and commissioning of a full-scale beech & hornbeam wood pellet production line with an output of 4-5 tons per hour. During the installation process, because the customer’s factory building...Read more -

Shindery vertical structure biomass powder/flour grinder is becoming more and more hot in Southeast Asia market

This kind of grinder is primarily used for superfine grinding of fiber texture material and sawdust, etc. As a kind of impact mill, it can also be used for pulverizing of non-metallic materials, feeds, agricultural products, and chemical products, etc. (Note: the Moh’s hardness of those mat...Read more -

Two sets of vertical structure wood powder machine/grinder export to Thailand

On January 1st,Shindery Machinery delivered 2 sets of vertical structure wood powder grinder to Thailand customer. This kind of grinder is primarily used for superfine grinding of fiber texture material and sawdust, etc. As a kind of impact mill, it can also be used for pulverizing of non-meta...Read more -

How to build rotary dryer machine stove?

Due to the special structure of the dryer stove and its large footprint, we usually recommend that customers build the stove locally. We provide detailed drawings and list all the materials needed to guide our customers in building furnaces. Of course, if the customer requests, our engineers can ...Read more -

How to crush wood log into wood chips even sawdust form?

Most customers are looking for one machine which can crush wood log directly into nearly sawdust form. Disc Wood chipper machine well suitable for this requirements,this wood crusher machine is the special chipping/crushing equipment for raw wood of 50-500mm (diameter).The diameter of wood sawdus...Read more -

Disc wood chipper and air flow pipe dryer are delivered to Bulgaria

This customer’s raw material is fresh wood log,he wanted to use the wood log to make chicken bed,wanted capacity is about 800kgs/hour. To realize this purpose,a disc wood chipper machine and air flow pipe dryer. The disc wood chipper can crush wood log and wood scraps into wood chips or eve...Read more -

How to crush wood chips into sawdust?

In order to facilitate transportation, many raw material suppliers will provide raw materials in the form of wood chips,so we need to add a raw material pre treat process before producing pellet fuel, that is, crushing wood chips into sawdust form. How to crush wood chips into sawdust? First, we ...Read more -

How to use wood waste material to make pellet fuel?

Wood processing factories often produce a lot of wood scraps. In the past, factories paid a certain fee to deal with these scraps. With the increasing demand for pellet fuel in the market, more and more factories find it is feasible to use these scraps to produce sawdust pellets for sale. So how ...Read more -

How to use wood veneer to make sawdust?

In the wood processing and production process,a large amount of veneer will be produced. How to deal with these veneers and create more benefits? The wood veneer can be crushed into sawdust form for the production of wood pellets for secondary use as fuel. The wood pellet can also be sold as comm...Read more