Factory supplied Wood Pellet Making Line - LGX560 Biomass Pellet Machine – Shindery

Factory supplied Wood Pellet Making Line - LGX560 Biomass Pellet Machine – Shindery Detail:

INTRODUCTION

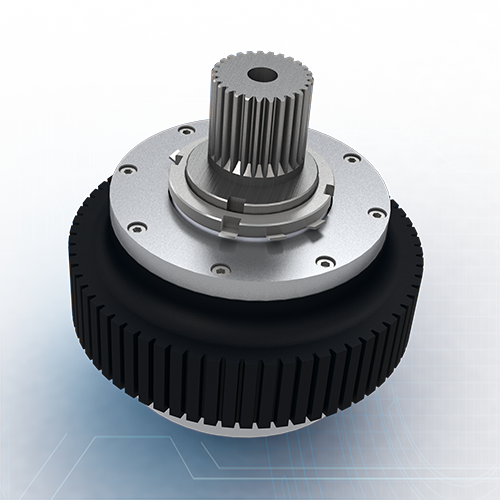

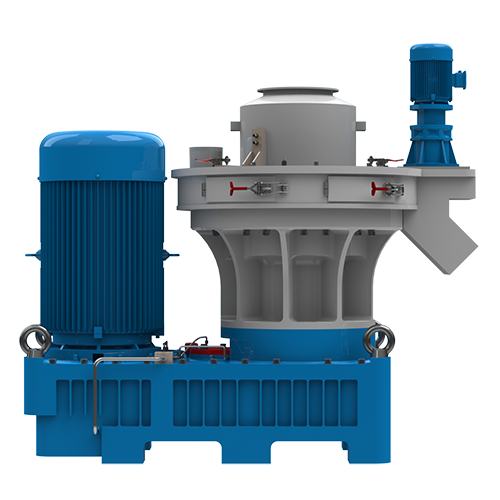

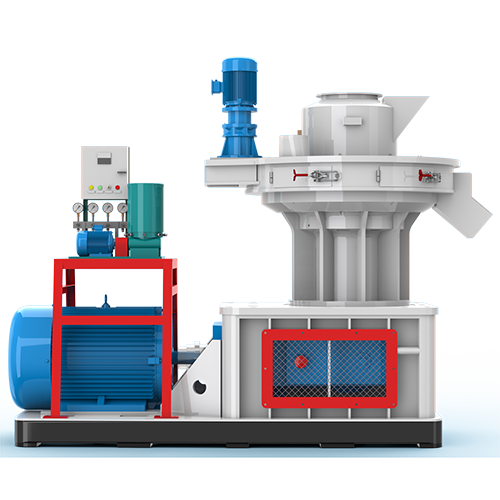

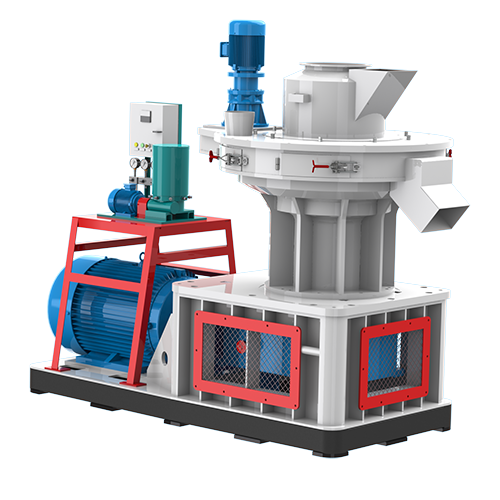

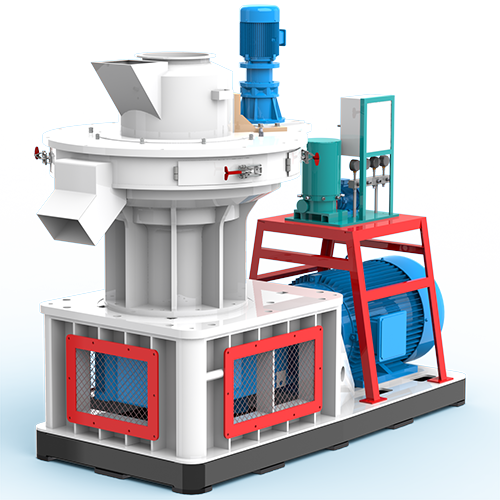

LGX-560 vertical ring die pellet machine absorbs the quintessence of various pellet machines both at home and abroad, the heart part adopts “double-layer die” as the unique structure. The rollers are made by abrasion-proof alloy steel, this pellet mill with characteristics of unique design, rational structure, lower power consumption, high efficiency, long lifetime. This machine is our initiative patent products in China through meticulous research and development, supplying the gap of vertical feeding ring-die pellet mill at home, reaches the international advanced level.

RAW MATERIAL

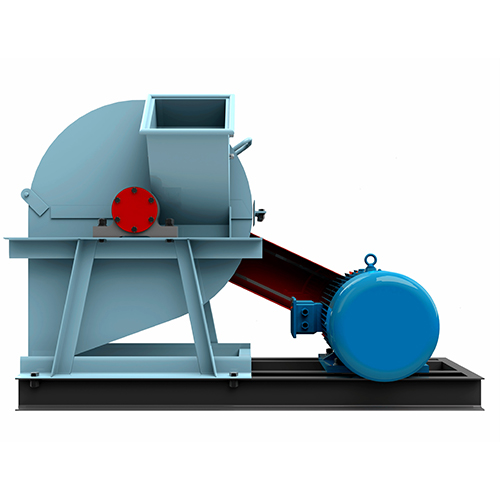

The equipment is applied to the material with low adhesiveness and low shaping ,such as the rice husk, sunflower seed husk, peanut shell and other fruit shell branch, trunk, bark and other wood waste; a variety of crop straws, rubber, cement ,ash and other chemical materials. The pellet mill is widely used in the feed plant, wood processing, fuel plant, fertilizer plant and chemical plant etc. It is the ideal pressing shaping equipment with low investment and high profit.

SEVEN CHARACTERISTICS

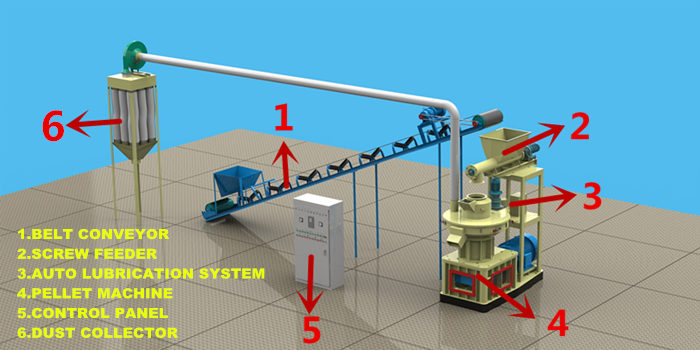

1.Feeding vertically and directly to pelletizing room.

2.Die static, rollers rotating, materials centrifugal, evenly distributed around.

3.Double-layer dies, up and down dual use, high capacity and energy saving.

4.Ring die, vertical structure, conducive to the pelletizing room cooling.

5.Independent output device, ensure formation rate of pellets.

6.Independent lubrication system, bring precise & automatic lubrication to bearings.

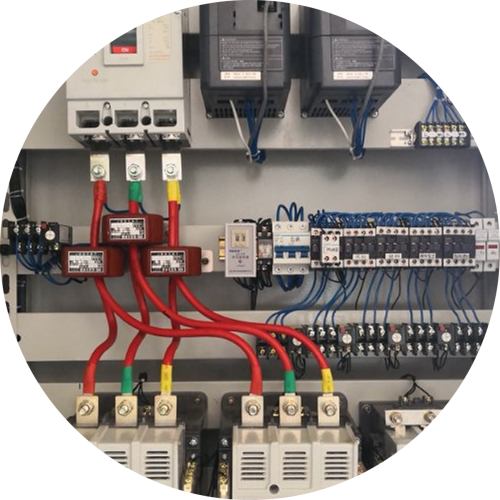

7.Feeding system is equipped with inverter which can bring stepless adjustable feeding speed.

|

Model |

LGX560 | |

| Power (kw) |

Main machine |

90 |

|

Pellet pusher |

1.5 | |

|

Lubrication pump |

0.37 | |

| Rotation speed (r/min) | 1450 | |

| Voltage (v) | 380 / customized ,3phase | |

| Pellet size (mm) | 4-12 | |

| Machine weight ( t ) | 5.6 | |

| External dimension (mm) | 2690*1250*2040 | |

| Ring die inner diameter (mm) | 560 | |

| Capacity (t/h) | 1.2-1.5 | |

How does LGX560 ring die wood pellet machine work?

Product detail pictures:

Related Product Guide:

Global Hybrid Solar Wind Energy Storage Market 2019 – Siemens Gamesa Renewable Energy, ReGen Powertech, General Electric | Hickory Wood Pellet Machine

10 BattleBots That Are Sad And Weak (And 10 We Want Protecting Us) | Mobile Hammer Crusher

We persist with the principle of "quality 1st, assistance initially, continual improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the standard objective. To great our service, we present the products and solutions while using the very good top quality at the reasonable cost for Factory supplied Wood Pellet Making Line - LGX560 Biomass Pellet Machine – Shindery , The product will supply to all over the world, such as: Lithuania , Kuala Lumpur , Netherlands , Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!