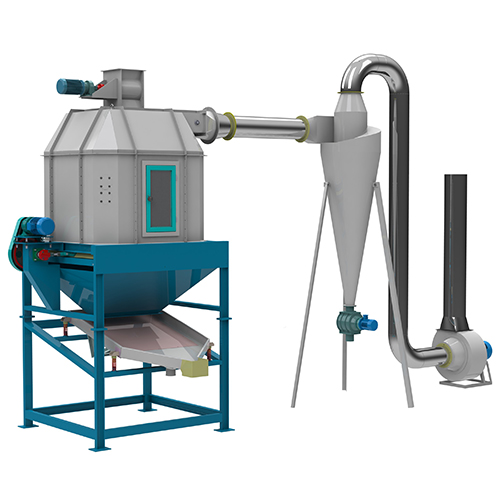

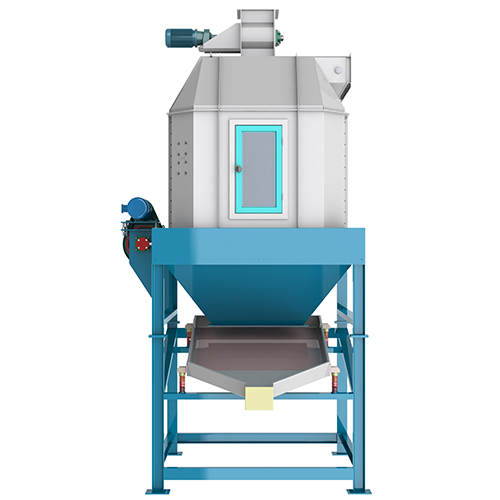

18 Years Factory Biomass Pellet Making Machine - Counter Flow Cooler – Shindery

18 Years Factory Biomass Pellet Making Machine - Counter Flow Cooler – Shindery Detail:

After pelletizing process,the pellet temperature will be about 70-80 degrees, and contain a certain amount of moisture. Use pellet cooler, can reduce the temperature of wood pellet,and during this process,the moisture will also reduce about 3%,to make sure the pellets can be easy storing.

FEATURES

(1)The counter flow cooler adopt counter. Current cooling principle to cool down the pellets wish high temperature and humidity, which avoid pellet cracking by the direct contact between hot pellets and cold airflow. so there is no quick chilling happens and pellet surface cracking can be prevented.

(2)Use closed unloader with large inlet area, so the cooling effect is significant.

(3)Adopts slide valve or tilting discharge mechanism with smooth and reliable motion, less pellets remain.

(4)Low energy consumption, easy to operate.

|

Model |

SKLN-3 |

SKLN-6 |

|

Inlet Air Lock (kw) |

0.55 |

0.75 |

|

Cooler Motor (kw) |

0.75 |

1.1 |

|

Vibration Screener (kw) |

0.12 |

0.12 |

|

Discharge Air Lock (kw) |

0.55 |

0.75 |

|

Bolwer (kw) |

5.5 |

7.5 |

|

Capacity (cool biomass pellets, t/h) |

2-6 |

6-9 |

|

External Dimension of Cooler (mm) |

2600×1700×3160 |

2700×2200×4225 |

Product detail pictures:

Related Product Guide:

AU Equipment Hosts Demonstration of OilQuick USA System | Hickory Wood Pellet Machine

Green wealth in oil palm | News | Eco-Business | Hickory Wood Pellet Machine

Adhering into the principle of "quality, provider, performance and growth", we now have gained trusts and praises from domestic and intercontinental consumer for 18 Years Factory Biomass Pellet Making Machine - Counter Flow Cooler – Shindery , The product will supply to all over the world, such as: San Diego , Tanzania , Ghana , Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

Cooperate with you every time is very successful, very happy. Hope that we can have more cooperation!